Daswell wet grinding mill for calcium carbonate is used to produce fine and high quality ultra fine ground calcium carbonate powder in wet milling way. In other words, the calcium carbonate particles are dispersed in a liquid by impact or by attrition. The fineness of the ground calcium carbonate can reach 2-6.5μm or even superfine. And with constant innovation and advanced design, Daswell wet mills for grinding calcium carbonate can be cost-effective, producing high capacity ground calcium carbonate with low consumption of energy. Daswell calcium carbonate vertical wet mills come with different sizes and grinding chamber volumes to meet customer’s needs of production capacity. According to customer’s needs, we will recommend the suitable vertical wet media mills for customers.

for Calcium Carbonate

Features of Vertical Wet Media Mill for Calcium Carbonate

- Flexible production line. Daswell wet grinding mill for calcium carbonate can work alone or paired with each other to produce ground calcium carbonate with different capacity. In this way, the vertical wet mill production line can produce calcium carbonate with desired fineness as well as high production.

- Compacted size. Daswell calcium carbonate vertical wet milling machines have compacted sizes. This means the wet grinding mills occupy small areas and reduce costs on construction sites.

- Low-energy consumption. Due to the advanced design and construct, Daswell vertical wet mills for calcium carbonate consume less energy in the grinding process.

- Robust design. Daswell calcium carbonate wet milling machines are made of quality steel which make the machines durable and reliable. Thus these wet grinders are low maintenance machines. What’s more, the interior of Daswell wet mills are made of abrasive-resistance materials so that they can work for long term.

- Controlled particle sizes. Daswell wet grinding mills are suitable for superfine calcium carbonate and other mineral slurry.

- Quality end product. Daswell wet mills for calcium carbonate can be equipped with ceramic wear protection to ensure high degree of whiteness. Except that, the finished ground calcium carbonate powder will have uniform shapes with consistent sizes.

- Cost effectiveness. Daswell calcium carbonate wet grinding mill can produce high capacity product with low energy consumption. Besides, these wet milling machines are suitable for continuous operation.

Calcium Carbonate Wet Grinding Mill

Calcium Carbonate Wet Grinding Mill

Daswell Calcium Carbonate Wet Grinding Mill

Henan Daswell machinery company is a leader in mineral processing, mainly non-metallic minerals such as calcium carbonate, quicklime, hydrated lime and ground silica. We are the single source for mineral processing plants. For Daswell provides tailored turnkey solutions for calcium carbonate plant, quicklime production line, hydrated lime process and other projects. That is, Daswell not only provides design and plan of your plants according to your needs, but also offers high quality complete sets of equipment. Daswell calcium carbonate wet grinding mill is a central piece equipment to produce ground calcium carbonate powder in a wet milling way. As usual, Daswell wet grinding mill for calcium carbonate are designed to be durable and reliable machine with optimum performance. They can produce high grade calcium carbonate powder with low energy consumption. Besides, they are the suitable grinders to produce ultra fine ground calcium carbonate powder. Whether your consideration is about costs, production capacity or end product quality, Daswell wet grinding mills can suit your needs accordingly.

Daswell Wet Milling Process for GCC Powder

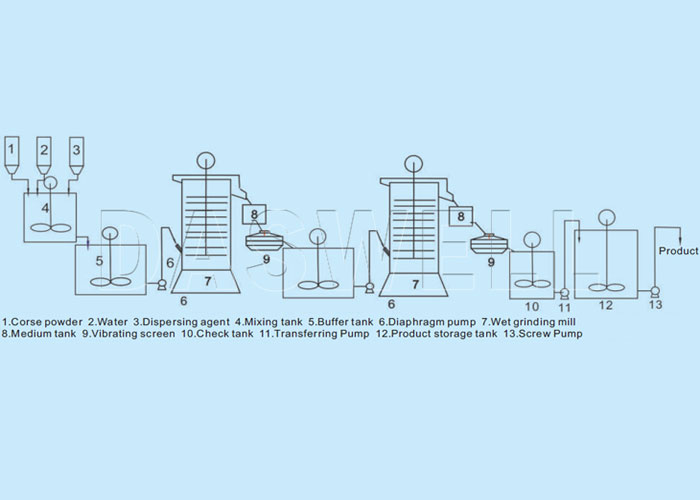

Daswell wet grinding mills can be used to process ground calcium carbonate, barite, kaolin and other material. Here we will take the ground calcium carbonate process for example. The first step is to blend the calcium carbonate with water. In the mixing tank, calcium carbonate coarse powder, water and dispersing agent are mixed. And then the mixture will go to the buffer tank. Through diaphragm pump, the calcium carbonate slurry goes into the vertical wet media mill. In the wet mill for calcium carbonate, the media in the wet mill will be activated to impact and ground the calcium carbonate slurry. From the wet media mill, the calcium carbonate product will go to the medium tank. Then it will go into check tank so that you can check the quality of calcium carbonate product. However, to get dry ground calcium carbonate powder, calcium carbonate from wet grinding mills will go through drying process. Under the function of hot-blast stove, the wet calcium carbonate will be transported to drying machine. And to protect working environment, dust collector is needed. Finally the finished ground calcium carbonate powder will go to the product silo. Of course, if you want produce coated calcium carbonate powder, you can also add a calcium carbonate coating machine.

Technical Parameter:

| Model | VMG1600 | VMG3000 | VMG3600 | VMG5600 |

| Fineness | -2μm, D60 | -2μm, D60 | -2μm, D60 | -2μm, D60 |

| Dry product productivity(t/h) | 2.0-2.5 | 2.5-3 | 3-3.8 | 4.5-5 |

| Dispersing agent consumption(kg/ton dry product) | <4 | <5 | <5 | <5 |

| Grinding media consumption(kg/ton dry product) | 0.2-0.4 | 0.3-0.4 | 0.3-0.4 | 0.3-0.4 |

| Power consumption(kw*h/ton dry product) | <45 | <40 | <40 | <40 |

Note: Feeding material is -45μm,D99, and solid content 70-76%.

Working Principles of Calcium Carbonate Wet Grinding Mill

Daswell wet media mill is an cost-efficient ultra fine calcium carbonate processing machine. By grinding calcium carbonate slurry, Daswell wet grinding mill can produce high quality ground calcium carbonate powder with desired fineness, high brightness, and uniform shape. To have a better understanding of Daswell wet mill, here we will introduce its working principles. Daswell wet media mills can charge the feed material from bottom to top or from top to bottom according to their different designs. When the wet grinding mill is activated by high-speed agitator shaft, the media in the mill will be full of energy. So when the material is pumped in the mill, this energy acts on the solids suspended in calcium carbonate slurry to reducing them in size. And the particle will disperse into the liquid for drying process or other uses. The media can be made of ceramic, steel, stainless steel and other materials according to the minerals to be ground and the needs of customers. And the factors that impact the ultimate size of end product is the size of mill media, the time material spend in the grinding chamber, the number of passes through the mill and the speed of agitator. So to get desired particle size of ground calcium carbonate powder, you can adjust these factors.