Limestone is abundant sedimentary rock consisting of high level of calcium carbonate. Limestone is a very useful industrial mineral that it is used widely in many industries, such as construction, paint, paper industries. Limestone is normally used in three forms. The first is natural form, such as ground limestone powder. The second form is calcined limestone or quicklime. And the third one is hydrated lime, getting by mixing quicklime with proper amount of water. Corresponding, there are respective processing plants: limestone grinding plant, limestone calcining plant, and hydrated lime plant. With rich experience and professional knowledge, Daswell offers turnkey solutions for limestone processing plant, including the limestone grinding plant, limestone calcining plant and hydrated lime plant. We not only help customers design and plan the plants, but also can supply quality equipment.

Limestone Processing Plant Design

Henan Daswell machinery has professional knowledge and rich experience in limestone processing. And we have delivered several successful limestone processing plants around the world, including limestone powder grinding plant, limestone calcining plant, and hydrated lime plant. And as a result, we have won the trust of our customers and formed long term business relationship. Daswell offers tailored turnkey solutions for limestone processing plants, including designing and planning plants and supplying relevant equipment. Daswell limestone processing plants, be the limestone grinding plant, limestone calcining plant or lime hydration plant, are designed and delivered according to customers’ needs, such as properties of raw materials, production capacity, end product quality, applications, and so on. With customers’ needs in mind, Daswell will make customers’ dream come true with our manufactured complete set of equipment.

Limestone Production Process

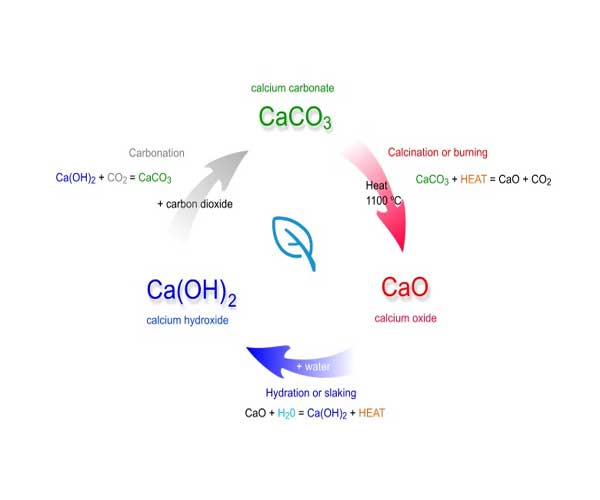

As stated above, limestone can used in three forms and as a result the limestone will go though several processes. Here are the basic processes: quarrying of limestone, washing and selecting limestone for further uses, grinding of limestone, calcination of limestone, and slaking of quicklime. Of course, these processes may not be necessary to present in every limestone processing plant. And in fact, these processes can be done in separate plants. In the limestone grinding plant, the limestone is ground in grinding mills to fine powder. And the ground calcium carbonate can used in paper and paint industries. For limestone calcining plant, the limestone is calcined in rotary kiln or vertical kiln to produce quicklime. In the hydrated lime plant, high calcium quicklime will react with water to make slaked lime.

Limestone Processing Equipment

As mentioned above, there are several processes that limestone should undergo, such as crushing, transferring, grinding, calcining and hydration process. So there are many machines in the processes. The common machines in these limestone processes include crusher, feeding devices, conveyor or bucket elevator, raw material silo and product silo, dust collectors and packing machines. Except these, there are other machines in the limestone processing. For example, in limestone grinding plant there are limestone grinding mills, such as ball mill and wet grinding mill. Besides, there are classifiers to further cut the limestone powder. In the limestone calcining plants, there are lime kilns such as rotary lime kiln and vertical lime kiln. And for rotary lime kiln, it often works with vertical preheater and vertical cooler to improve productivity efficiency. As for hydrated lime plant, there are hydrators to hydrate quicklime and water.

Limestone Grinding Plant

Limestone grinding plant is a production line to grind limestone in limestone grinding mills to obtain fine limestone powder, that is ground calcium carbonate powder. To get fine and ultra fine ground calcium carbonate powder, limestone grinding mills, such as ball mill and vertical wet grinding mill, are often used. For the ball mill for ground calcium carbonate, it often works with air classifier to produce controllable fineness of ground calcium carbonate powder. As for the wet grinding mill, it makes ground calcium carbonate powder in a wet grinding way. To get the suitable limestone grinding plant, customers should know the properties of raw materials, the required fineness of end product, the production capacity and the applications of end product. According to customers’ needs, Daswell offers turnkey solutions for limestone grinding plant, including designing and planning of plants, providing quality equipment.

Limestone Calcining Plant

Limestone calcining plant is also known as quicklime plant. The plant will calcine limestone to obtain quicklime or burnt lime. Usually, there are two kinds of kilns to burn the limestone. One is rotary lime kiln and the other is vertical lime kiln. In the kilns, the limestone will be processed with high temperature to produce quicklime, while the carbon dioxide is driven off by air blowers. Daswell modern rotary lime kiln often includes vertical preheater and vertical cooler to improve production efficiency and reduce costs. Daswell limestone calcining plant are also customized designed to meet customers’ needs. And except for new quicklime plant, Daswell also provides services to upgrade existing lime calcining production plant.

Lime Hydration Plant

Lime hydration plant is to mix quicklime with water to produce hydrate lime, also called slaked lime. Firstly, quicklime is crushed to required sizes. Then proper amount of quicklime and water are mixed and fed into hydrators. For obtain high quality hydrated lime, there are more than one hydrators to hydrate the quicklime.

Daswell Limestone Processing Plant

With professional expertise and rich experience, Daswell offers tailor-made turnkey solutions for limestone processing plants, including limestone grinding plants, limestone calcining plants and lime hydrated plants. Daswell is one source supplier for limestone processing plants, for we not only design and plan the plants, but also provide quality equipment for these limestone processing plants. Daswell limestone processing plants are all customized designed to meet customers’ needs and produce high quality end products with great efficiency.