Quartz grinding plant is a silica powder making production line. It includes a set of processing machine to produce ground quartz powder. Quartz is a crystallized form of silicon dioxide, also known as silica. According to Wikipedia, quartz is the second most abundant mineral in earth’s continental crust. Its unique properties, such as high hardness and high wearing resistance make quartz one of the most useful natural substances. As a result, ground quartz has been widely used in industries, like glass making, paint, adhesives and plastic industries. So it is of high economic value to build quartz powder production plant. According to customers’ needs, Daswell offers turnkey solutions for quartz grinding plants, including plant designing, planning and supplement of relevant quality equipment.

Features of Daswell Quartz Power Production Plant

- Turnkey solutions. With great expertise and rich experience, Daswell offers tailored turnkey solutions for silica powder processing plant, including designing plants, providing equipment, offering after-sales services and so on.

- Robust designs. All the machines for Daswell ground silica powder processing plant are made of high grade materials so that they can work smoothly for long time.

- High purity ground silica. The equipment for Daswell quartz grinding plant is equipped with ceramic plates and so on to avoid pollute the ground quartz powder.

- High quality quartz powder. Daswell silica powder production line can produce quality ground quartz with high purity, great whiteness, and great uniform and consistency.

- Various fineness ranges. Daswell quartz grinding plant with ball mill and classifier system can make controlled fineness of ground silica in one production line for different usages.

- PLC controls. Daswell quartz grinding plant is fully controlled by computer, which makes the silica power making plant easy to operate and save labor costs.

Ground Silica Production Process

Quartz Powder Processing Machine

According to customers’ needs in product applications, production capacity and so on, Daswell offers customized turnkey solutions for silica ground powder production lines. When it comes to quartz powder processing machine, the most common and suitable solution for silica powder production plant is the ball mill and air classifier system. For the system can make high capacity of ground quartz with various fineness but great uniformity and whiteness. Mainly the ground quartz powder processing machinery includes crusher, bucket elevators, vibrating feeding machine, raw material and product silos, quartz grinding ball mill, air classifiers and packing machines. All these facilities are controlled by PLC based system, so the whole quartz grinding plant is easy to operate and maintain. All the quartz powder making machines, designed and manufactured by Daswell, are made of high quality materials to be durable and reliable enough for long working life.

Daswell Silica Powder Processing Plant

Henan Daswell machinery is specialized in mineral processing, such as calcium carbonate plant, quicklime plant, hydrated plant and quartz powder plant. Daswell has years of experience in designing and planning these mineral processing plants according to customers’ needs. Besides, Daswell designs and manufactures complete sets of equipment for these mineral processing plants. And Daswell has successfully implemented several mineral processing plants around the world, which has earned high praises from customers. In all, Daswell is the one source manufacturer and supplier of mineral processing plants. Daswell silica powder processing plant often uses the ball mill with classifier system to produce ground quartz with great whiteness, uniform and consistency.

Quartz Grinding Ball Mill

Ball mill is the most common quartz grinding mill. The media balls inside the ball mill can ground quartz to fine powder. And the fineness can be controlled by the speed of the ball mill, the sizes and quantity of ball media. To obtain ultra fine quartz powder, the quartz grinding ball mill should work with primary and even secondary classifiers. For the air classifiers can cut the ground quartz processed from the ball mill to more fine powder while reject the coarse powder. Paired with air classifier, ball mill for grinding quartz can produce high capacity of ground quartz powder with great quality.

In fact, to ensure the high purity of ground quartz, Daswell quartz grinding machines, especially the ball mill and classifier are specially designed. For example, the interior of quartz grinding ball mill is equipped with ceramic plates so to reduce the impurities of quartz powder.

Quartz Grinding Process

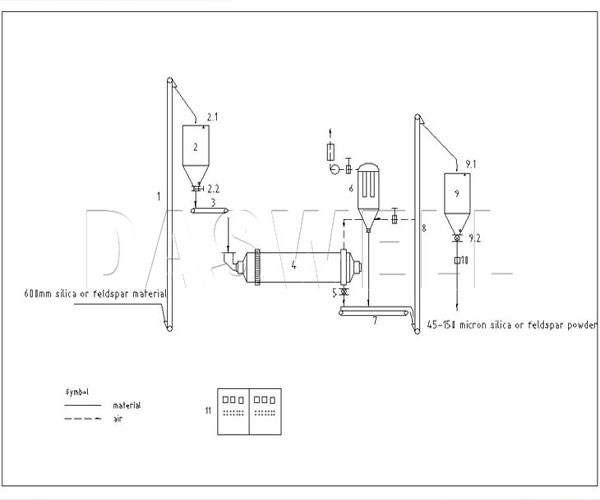

The ground silica manufacturing process is one in which involves a series of processes, such as crushing, transferring, material feeding, grinding, classification and packing. Here is the detailed quartz grinding process. Firstly, the quartz is crushed to required sizes and then it will be transferred to raw material silo through bucket elevator. Using vibrating feeding devices, the required sizes of quartz will be fed into the quartz grinding ball mill. In the ball mill for grinding quartz, the quartz will be ground to fine powder due to the impact of media balls in the ball mill. Then the processed quartz powder will be transferred to classifier through bucket elevator for classification. In the classifier, the quartz powder will be further cut into more fine powder, while coarse powder will be rejected for further grinding in the ball mill with raw material. For the desired quartz powder, it will be transferred to product silo through bucket elevator. Finally, the ground quartz will be packed automatically or by human.

Quartz Powder Uses

Quartz is the second most abundant mineral on earth. Its Mohs harness value is seven, which makes quartz harder than most substances and more durable. And quartz is chemically resistance in contact with most substances. Due to its physical and chemical properties, ground quartz has many applications. Ground quartz is often used as fillers in paint, adhesives and plastic industries. For the ground quartz makes the end products more durable and wear-resistant. And high purity quartz powder can also provide high whiteness. Besides, silica powder is also used as abrasive for grinding media, sand blasting and so on. And its luster and color also makes it useful for glass making industry. So it is of great profitability to build quartz grinding plant. And Daswell is the one source supplier for silica powder production plant, including designing and planning plants and providing quartz grinding machines. With rich experience and professional knowledge, Daswell has finished several successful quartz grinding plants projects worldwide. For more detailed information, please contact us as soon as possible.