The new type of vortex mill coating machine with classifier is the most advanced coating solution for calcium carbonate now in China. It is mainly used for surface modification of powders and film forming treatment. It can improve the compatibility between inorganic mineral fillers and organic polymers. Because of its wide application and high working efficiency, the demand of vortex mill powder coating machine is increasing. It is suitable for the modification of various materials, such as heavy calcium carbonate, light calcium carbonate, caolin, talc, quartz powder, mica, silica, zinc oxide, magnesium hydroxide, alumina, etc, which can totally meet your requirements. Any demand, welcome to inquiry now!

Characters of vortex mill coating machine

- This vortex mill machine adopts the principle of high-speed eddy current mixer, which can atomize the modifier and coat the surface of ultrafine powder by adsorption, so as to achieve the purpose of powder modification with very little amount of modifier.

- Our coating production line is equipped with a super fine classifier system, which can remove the agglomerated particles in the modification process immediately, to ensure that the activation rate is above 98% at the lowest level, generally up to 99%, and the product quality is stable.

- With less stearic acid consumption, to get better result, its coating rate is high. The same activation rate, its stearic acid consumption is lower than other types of modification machines. This can not only reduce your initial cost of purchasing modifier, but also increases your profits of finished products.

- The strong eddy current flow field makes its line speed up to 115m/s, and the material can be crushed instantly. At the same time, the material stays in the cavity for a short time, no temperature rise.

- Equipped with shunt classification system, it can effectively and accurately divide the product into different powder grades.

| Model | Max. Capacity(t/h) | Coating Power Size(μm) | 10μm GCC(t/h) | Coating Rate(%) |

| UCOAT500 | 2 | 5-23 | 1.4-1.5 | >98 |

| UCOAT750 | 3 | 5-23 | 2.8-3.0 | >98 |

| UCOAT1000 | 6 | 5-23 | 4.5-5.0 | >98 |

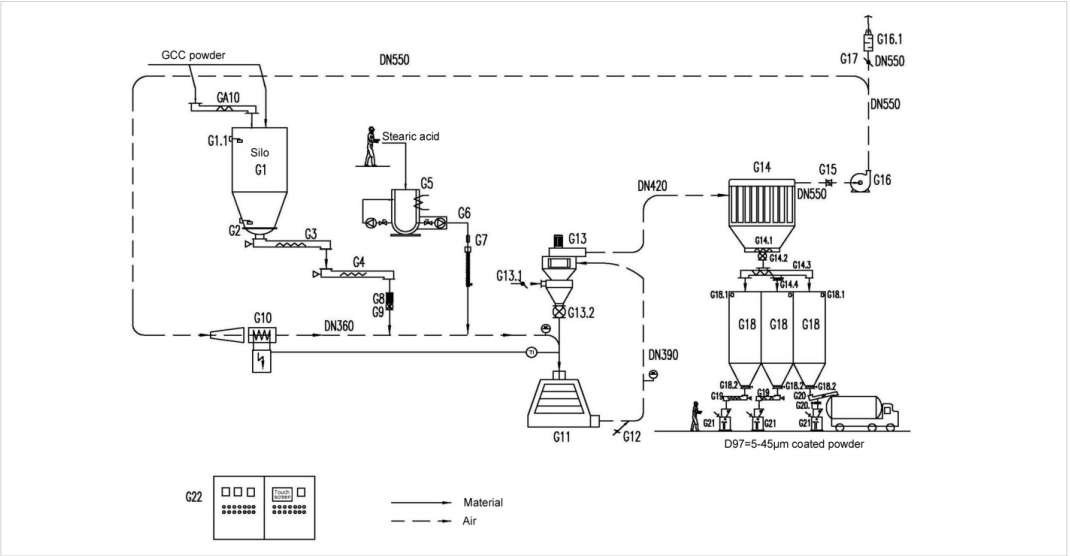

The flow chart of coating machine

The working flow of vortex mill coating machine for calcium carbonate powder is simple. First of all, calcium carbonate and modifier need to be sent to a screw conveyor for mixing after weighing. Then, the mixed materials are sent from the hot air stove to the vortex mill powder coating machine for high-speed stirring and coating. The coated material enters the classifier with the airflow. Qualified materials are collected and cooled in the dust collector for packaging. The unqualified materials are discharged from the classifier and enter the reformer again for depolymerization and coating, so as to carry out recycling production.

The core of what it does is the materials are evenly into the crushing chamber by charging system, crushed by high speed rotating plate of strong shocks. The crushing rotor is composed of multilayer crushing plate and multiple crushing blade. The materials are crushed by various crushing forces such as shearing, collision and friction. The qualified materials enter the collection area with the updraft for collection, and the coarse materials return to the crushing area for secondary crushing.

Why should the powder be modified?

Why should the powder be modified? There are several reasons.

- Improve compatibility and enhance dispersibility. Surface modification is one of the necessary processing methods for inorganic filler to change from general incremental filler to functional filler. At the same time, it also provides a new technical method for the development of polymer materials and organic or inorganic composite materials, which is one of the main purposes of powder surface modification.

- Improve the dispersion of paint or paint, and improve the luster of the paint, coloring power, hiding power, heat resistance, antibacterial and mildew resistance and so on.

- Endows the powders with new functional characteristics and expands the application field.

- Improve the adsorption and catalytic properties of the powder.

| Model | Max. Capacity(t/h) | Coating Power Size(μm) | 10μm GCC(t/h) | Coating Rate(%) |

| UCOAT500 | 2 | 5-23 | 1.4-1.5 | >98 |

| UCOAT750 | 3 | 5-23 | 2.8-3.0 | >98 |

| UCOAT1000 | 6 | 5-23 | 4.5-5.0 | >98 |

Application of vortex mill machine

After the powder is modified, it can be used in glass fiber, coating, sealant, plastic, rubber, PVC, decorative paints, slippers, textile and other fields. The modified powder can meet the problem of compatibility with resin in polymer materials such as plastic and rubber, and effectively solve the problem of reducing the performance of the product due to agglomeration of inorganic fillers. In addition, in order to better play the role of nano powder, nano powder is generally modified. The powder modifier was uniformly coated on the surface of the nano powder, so as to improve the function and characteristics of the nano powder.

Our Daswell Machinery provides different specifications of vortex mill powder modification machine for our customers, UCOAT500, UCOAT750 and UCOAT1000. You can talk with our sales manager for the details about the coating machine you want to buy. And then, they will give you professional advice according to your requirements. Therefore, if you have any demand, welcome to contact us. We can help you get a satisfied vortex mill coating machine.